Drilling and Tapping originally machining is extremely common. General desktop drilling, milling machines, machining centers computer can perform the job. When the work piece is growing, this job more difficult, for example: a large steel plate and engaging public construction use.

It is difficult

1 How to put large parts,

2 How to find large power up processing.

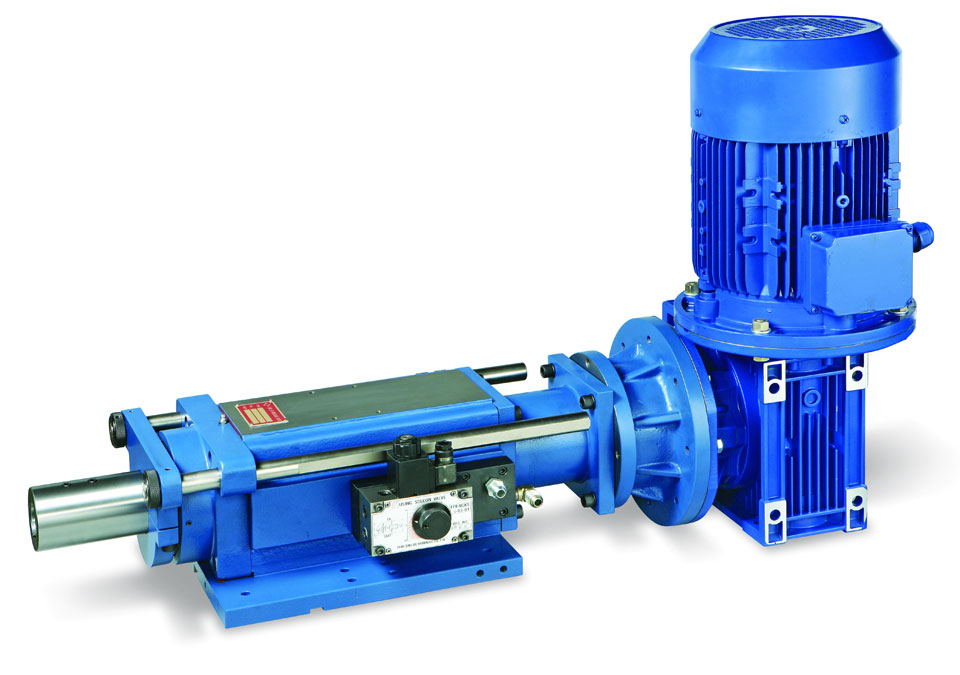

To solve the above problems, according to the Taiwan side technology companies need to design and manufacture a large-scale drilling power, model FD86-200, 140 mm in diameter Built-cylinder, can produce three tons of thrust. The maximum drilling capacity of up to a diameter of 50mm. Drilling is the largest commercially available power head. Then install the power head on the gantry drilling machine. This is the most common solution.

After drilling, if you want it, the higher the degree of difficulty tapping in the same position. Also how to display the work, how to find a problem tapping the power head. So Fang Technology has developed a hybrid power head drilling and tapping, Model: FD86/85N. It is the drilling and tapping two power heads combine in one. In addition, to solve the problem of drilling tapping outside the workpiece does not need to be moved. Application in the future, we can see in gantry-type machining on more and more composite power head unit.